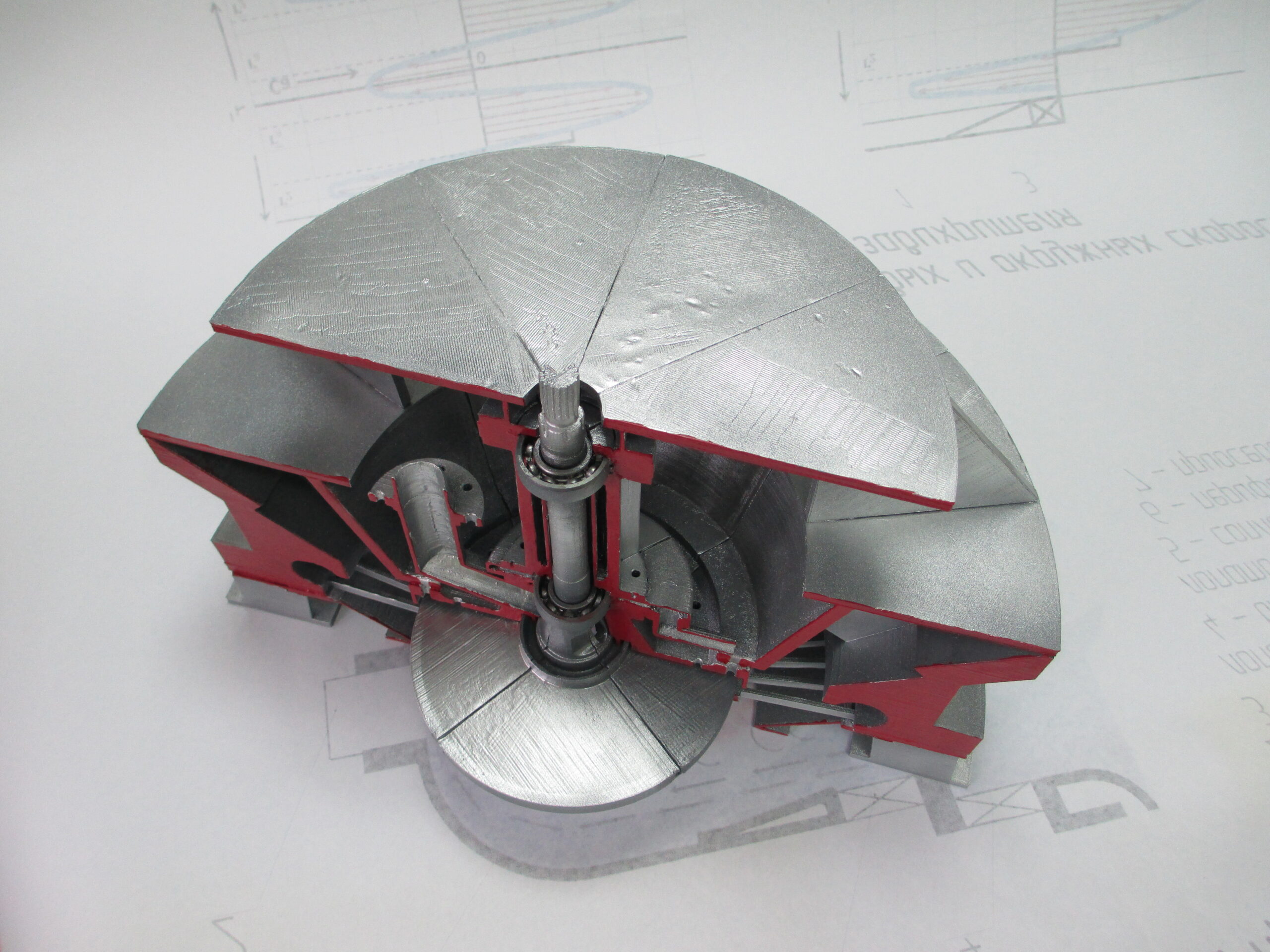

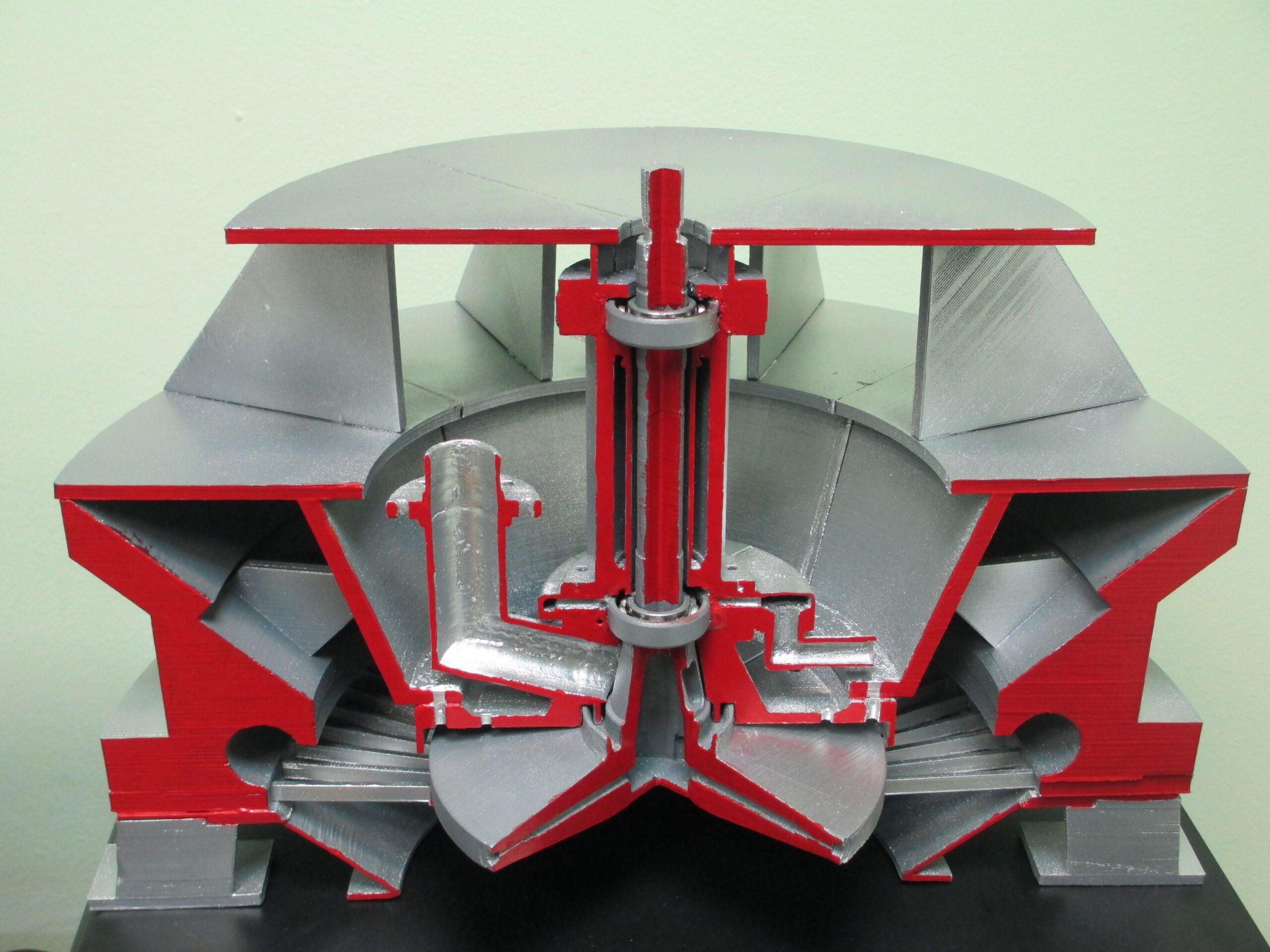

ROTOR DISINTEGRATOR

A Breakthrough in disintegrating Technology

This invention introduces a revolutionary method and apparatus for breaking down complex hydrocarbon structures in feedstocks such as heavy crude oil, bitumen, oil sands, and refinery streams. This technology has significant potential to revolutionize the hydrocarbon processing industry by facilitating enhanced separation and refining processes.

Transforms Industrial Byproducts into Valuable Resources

This technology confronts a significant environmental issue: the accumulation of waste and residual materials from various industrial processes, including mining and hydrocarbon processing. These materials can contaminate land and water, but current methods to address them are often inadequate.

This technology provides a more sustainable approach by facilitating the processing of these materials, minimizing environmental impact and promoting resource utilization.

How much is to much?

The vast tailings ponds left behind by oil sands mining in Alberta represent a significant environmental and economic challenge, with cleanup costs estimated to range from $30 to $130 billion. Traditional remediation methods struggle with slow processing times, high energy consumption, and can introduce their own environmental drawbacks.

Eirex’s innovative cavitation technology offers a promising alternative. By harnessing the power of hydrodynamic cavitation to break down complex hydrocarbon mixtures, Eirex can potentially achieve faster processing, improved resource recovery, and a substantial reduction in remediation costs. This technology presents a viable pathway to more sustainable and economically efficient tailings pond management, addressing a critical issue for the oil sands industry.